PUMP TUBING

Drifton offers a wide range of pump tubing for peristaltic pumps, carefully selected to meet various needs in industrial and laboratory environments.

Our tubing is supplied by three leading manufacturers:

Innovapure – A high-tech manufacturer offering solutions for medical and biopharmaceutical applications, with a focus on precision and reliability. Their tubing meets stringent GMP standards and is especially suitable for clean and sterile environments.

See their catalog here: Innovapure catalog - PDF

Ami Polymer – A specialist in silicone products, providing flexible and chemically resistant tubing ideal for applications in biotechnology and pharmaceutical industries where sterility and high resistance are crucial.

See their catalog and chemical resistance chart here: Ami Polymer Catalog - PDF and Ami Polymer Chemical Resistance Chart - PDF

Masterflex/Tygon – Masterflex provides a versatile range of Tygon tubing, known for its durability and chemical compatibility. This tubing is designed for demanding environments and is widely used in everything from laboratories to food production.

See the Masterflex pump tubing selection guide here: Masterflex Tubing Selection guide - PDF

Our range includes everything from basic single-channel pump tubing to color-coded microflow tubing with 3-stoppers, designed for multichannel pump heads. When selecting tubing, consider requirements for temperature, wear, and chemical resistance, or if it needs to function in sterile or inactive environments.

CHOOSE TYPE OF PERISTALTIC PUMP TUBING

You can choose from peristaltic pump tubing for

- Laboratories

- Pharmaceutical and medical use

- Biological applications

- Industrial use

- MEK and other aggressive solvents

- Concentrated acids and corrosive solvents

- Sensitive liquids

- Foodstuffs

- Beverages

- Gasoline, kerosene, fuel oil, cutting compounds and glycol-based coolants

Regulatory Approval

Regulatory approval is particularly important in the pharmaceutical industry, where everything that comes into contact with the final product must conform to specific standards and guidelines. As a result, many tubing materials are designed to meet these various regulatory approvals, including those issued by the United States Pharmacopoeia (USP), European Pharmacopoeia (EP), U.S. Department of Agriculture (USDA) and National Sanitation Foundation (NSF).

Recommendation for new tubing

New tubing requires a running-in period if constant and reproducible flow rates are required. It is recommended that new tubing be placed in the pump head and run-in with water or the mediumfor at least 1 to 3 hours before the application is started.

Service life of tubing in peristaltic pumps

The service life of the tubing in peristaltic pumps is affected by the conditions of use and the equipment used. In addition, it depends on the size and thickness of the wall of the tubing. The data on the life span of the tubing is for information only and should not be used for specification purposes.

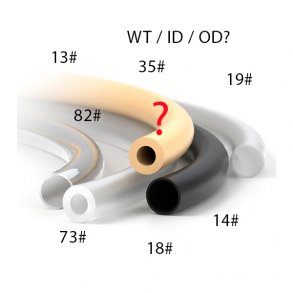

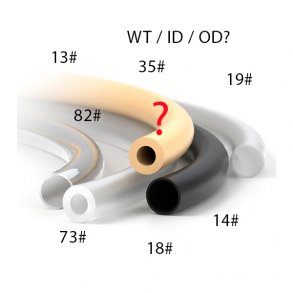

Tubing Specifications

If you have any questions or need more information, please contact us!